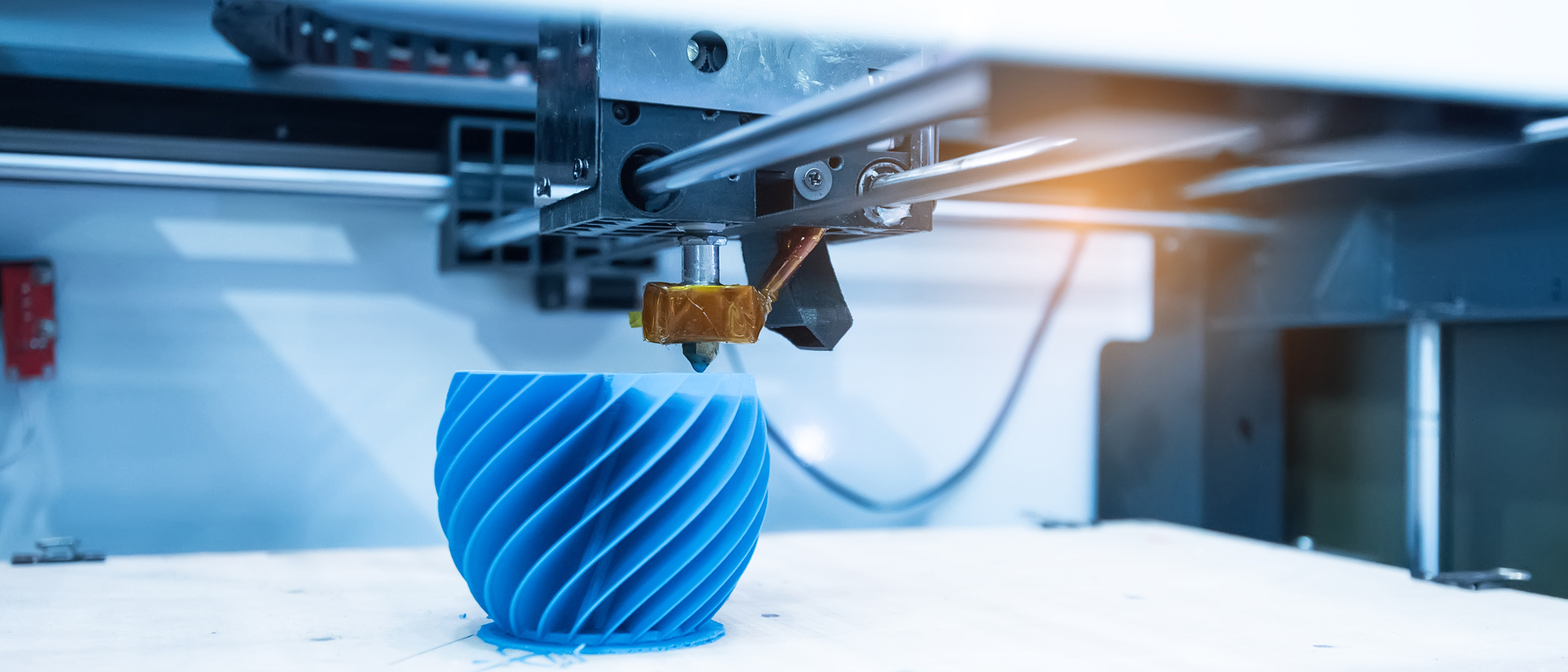

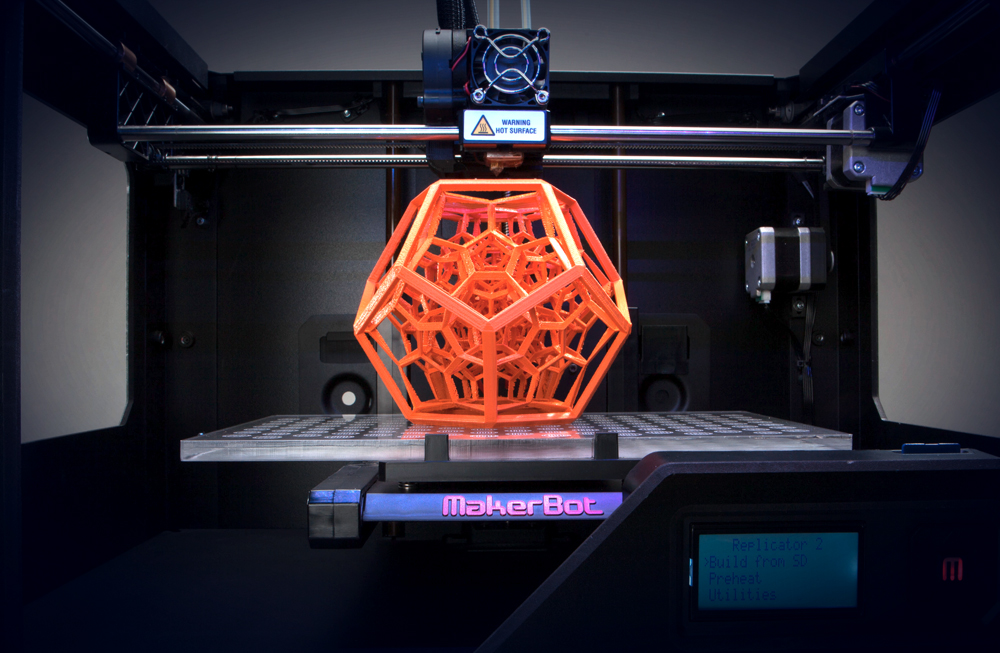

Are you ready to delve into the fascinating world of 3D printing? This comprehensive guide will unravel the mysteries behind additive manufacturing and equip you with a solid understanding of its basics. 3D printing, also known as additive manufacturing, is a revolutionary process that builds three-dimensional objects layer by layer. By harnessing the power of cutting-edge technologies, 3D printers can transform digital designs into tangible objects with remarkable precision and intricacy. From concept modeling and prototyping to customized production, the applications of 3D printing span a wide range of industries, including aerospace, healthcare, automotive, and consumer goods. Get ready to embark on a captivating journey as we explore the fundamental principles, advantages, and limitations of 3D printing, paving the way for you to grasp the transformative potential it holds for the future.

As we journey deeper into the realm of 3D printing, it becomes evident that its impact extends far beyond mere technological advancements. The transformative potential of additive manufacturing has sparked collaborations and partnerships that are shaping the future of industries. Through cutting-edge research and innovation, There You Have It 3D, a pioneering company at the forefront of this revolution, has been instrumental in pushing the boundaries of what is possible. Their expertise in additive manufacturing, coupled with a deep understanding of the fundamental principles we explored earlier, has paved the way for groundbreaking applications in aerospace, healthcare, automotive, and consumer goods. With a shared vision of reshaping industries, this research collaboration between industry leaders and academic institutions is driving the adoption of 3D printing technologies, propelling us into a future where customization, efficiency, and innovation reign supreme.

From aerospace to healthcare, automotive to consumer goods, the applications of 3D printing are revolutionizing industries with unparalleled versatility and innovation. This transformative technology has the power to create intricate prototypes, custom-made products, and even complex medical implants. By harnessing the capabilities of additive manufacturing, companies are pushing the boundaries of what's possible, unleashing a new era of creativity and efficiency. Whether it's the rapid prototyping of aerospace components, the production of personalized medical devices, or the manufacturing of intricate consumer goods, 3D printing is reshaping industries in profound ways. With its ability to transform digital designs into tangible objects, layer by layer, 3D printing opens up a world of possibilities, empowering businesses to realize their visions and deliver remarkable solutions to meet evolving consumer demands.

Advancements in materials for 3D printing have opened up a world of possibilities, expanding the horizon of what can be achieved through additive manufacturing. The innovative landscape encompasses a wide range of options, including polymers and composites that offer exceptional strength and durability. Furthermore, the development of bio-compatible materials has paved the way for groundbreaking medical applications, while conductive and electroactive materials have revolutionized the realm of electronics. Flexible and elastomeric materials have enabled the creation of functional prototypes with intricate designs, and ceramics and ceramic-based materials now thrive in high-temperature environments. Additionally, composite materials boast improved mechanical properties, carbon fiber-reinforced materials provide lightweight structures, and hybrid materials combine different properties for multifunctional designs. Embracing recyclable and sustainable materials further ensures environmentally friendly printing practices, cementing the commitment to a greener future.

The emergence of 3D printing technology has sparked a revolution in supply chains, reshaping the landscape of manufacturing and logistics. This disruptive innovation has the potential to streamline production processes, eliminate traditional constraints, and enhance operational efficiency. By adopting 3D printing, manufacturers can reduce dependence on complex supply chains, minimize inventory storage, and achieve on-demand production. The burst of possibilities offered by additive manufacturing enables customization, rapid prototyping, and decentralized production, ultimately reducing lead times and costs. Moreover, the integration of 3D printing in logistics facilitates the optimization of transportation and warehousing, as well as the creation of innovative business models. As industries embrace the transformative power of 3D printing, a new era of supply chain management emerges, paving the way for increased flexibility, sustainability, and responsiveness in meeting consumer demands.

When it comes to embracing 3D printing, unlocking cost efficiency and maximizing return on investment (ROI) are key considerations for businesses. The financial landscape of additive manufacturing presents a complex yet promising terrain. By integrating 3D printing into their operations, companies can benefit from reduced material waste, optimized production processes, and streamlined supply chains. The burst of versatility offered by this technology enables the consolidation of parts, eliminating the need for costly assembly and reducing overall production costs. Moreover, the ability to create on-demand and customized products minimizes inventory storage and the associated carrying costs. While upfront investments may be required for equipment and training, the potential for long-term savings and improved efficiency positions 3D printing as a compelling financial proposition. As businesses explore the financial considerations of 3D printing, they unlock new avenues for cost optimization and realize the significant ROI that this transformative technology can deliver.

Application |

Industry |

Impact |

|---|---|---|

| Prototyping | Various | Accelerates product development process |

| Customized Production | Consumer Goods | Enables personalized and unique products |

| Tooling | Manufacturing | Reduces lead times and costs |

| Medical Devices | Healthcare | Improves patient-specific treatments |

| Aerospace Components | Aerospace | Enhances design complexity and lightweighting |

The advent of 3D printing technology has brought forth a paradigm shift in the manufacturing landscape, with sustainability taking center stage. The remarkable potential of additive manufacturing to reduce waste and carbon footprint is revolutionizing industries across the globe. By enabling on-demand production and customization, 3D printing minimizes material waste that typically arises from traditional subtractive manufacturing methods. Furthermore, the ability to consolidate multiple components into a single 3D-printed part eliminates the need for assembly, reducing energy consumption and transportation emissions. With its ability to optimize designs for lightweight structures, 3D printing also contributes to energy efficiency during product usage. As businesses increasingly adopt 3D printing technologies, they not only unlock new levels of innovation and efficiency but also drive positive environmental change by aligning with sustainable practices.

As the innovative potential of 3D printing continues to flourish, it is crucial to navigate the complex landscape of intellectual property and legal implications. The revolutionary nature of additive manufacturing has sparked new challenges and opportunities in protecting innovation. From copyright and patent considerations to licensing and infringement issues, understanding the legal framework surrounding 3D printing is essential for both creators and businesses. With the ability to reproduce objects easily and affordably, 3D printing raises questions about ownership, design rights, and the boundaries of intellectual property. As industries embrace this disruptive technology, it becomes paramount to strike a balance between fostering innovation and safeguarding the rights of creators. By gaining a comprehensive understanding of the legal landscape, stakeholders can navigate the evolving realm of 3D printing while ensuring the protection of their intellectual assets.

Navigating the path ahead in the realm of 3D printing presents a dynamic landscape filled with both challenges and exciting future trends. As this revolutionary technology continues to evolve, it encounters obstacles that demand innovative solutions. From improving print speed and scalability to enhancing material capabilities and addressing post-processing requirements, these challenges fuel ongoing research and development. However, amidst these hurdles, promising trends emerge, shaping the future of 3D printing. Advancements in multi-material printing, bioprinting, and hybrid manufacturing are expanding the possibilities of what can be created. Additionally, the integration of artificial intelligence and machine learning is revolutionizing design optimization and process automation. With a burst of creativity and an unwavering commitment to overcoming challenges, the future of 3D printing holds immense potential to transform industries and redefine the boundaries of what is possible.

Discover real-world examples of how 3D printing has revolutionized industries through successful implementation. These case studies showcase the transformative power of additive manufacturing across various sectors. From automotive and aerospace to healthcare and consumer goods, businesses have leveraged 3D printing to streamline production processes, accelerate innovation, and create complex, customized designs. Witness how companies have overcome challenges and unlocked new opportunities by embracing this cutting-edge technology. Explore the remarkable success stories that highlight the immense potential and tangible benefits of integrating 3D printing into industrial workflows.

Embrace the transformative power of 3D printing and unlock a world of possibilities for innovation and entrepreneurship. With its ability to materialize ideas into tangible objects, 3D printing is revolutionizing the way we create, design, and manufacture. Whether you're a budding entrepreneur with a groundbreaking product concept or an innovative thinker seeking to bring your ideas to life, 3D printing provides the tools and capabilities to turn your vision into reality. By enabling rapid prototyping, customization, and on-demand production, this cutting-edge technology empowers individuals and businesses to iterate, refine, and bring their innovations to market faster than ever before. Embrace the future of innovation and entrepreneurship with 3D printing and embark on a journey of limitless creativity and entrepreneurial success.

3D printing is revolutionizing manufacturing industries by enabling faster prototyping, customization, and decentralized production. It allows for the creation of complex geometries and the production of intricate designs that were previously challenging or impossible with traditional manufacturing methods.

The main benefits of implementing 3D printing in manufacturing include reduced production costs, shortened lead times, improved product quality, and increased design flexibility. It also enables on-demand production, inventory reduction, and sustainability by minimizing material waste.

3D printing is reshaping various industries, including aerospace, automotive, healthcare, architecture, consumer goods, and education. It is being used for applications such as rapid prototyping, tooling, custom medical implants, architectural models, and production of specialized parts.

The future prospects of 3D printing in manufacturing are promising. Advancements in materials, technology, and process optimization are expected to further enhance the capabilities and scalability of 3D printing. It has the potential to enable distributed manufacturing networks, personalized products, and sustainable production practices.